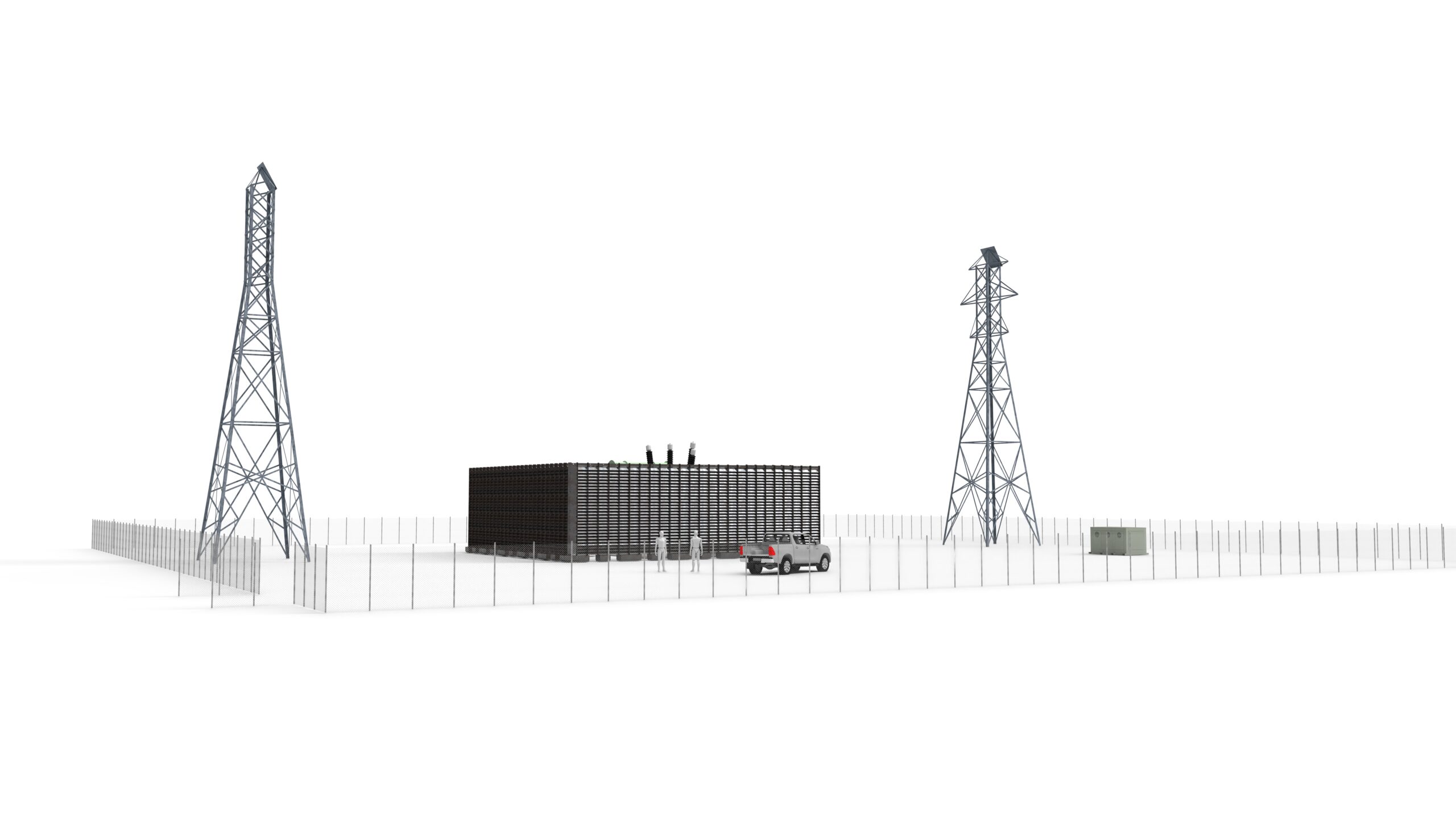

Grid Guardian is a company dedicated to securing utility-scale power management and distribution networks, high-visibility public facilities, and commercial off-grid power generation sites. Developed by a dedicated Team of former US Defense Contractors with battle-proven expertise in mobility, survivability, and crew protection systems, the Field Shield product line is a class leading solution without rival.

At Grid Guardian, we are redefining the landscape of securing domestic power distribution networks by deploying modern survivability techniques that are actively deployed within the US Department of Defense. Operated by a team of highly skilled defense contractors who are committed to delivering excellence in the protection of critical infrastructure apparatus, commercial/civilian assets and public facilities.

Security breaches against the U.S. power grid reached an all-time reported high in 2023, according to data Utilities submitted to the Dept. of Energy.

The Federal Energy Regulatory Commission (FERC) has advised Utilities to strengthen their physical security plans for both rural and urban power distribution sites after a 71% uptick of physical attacks on the Nation’s electrical grid since 2021.

We take pride in the exceptional durability and security of our systems. Each product is rigorously test certified to withstand straight-line wind speeds of up to 200mph. Our bullet-resistant armor is U.S Military Grade and meets additional standards including NIJ-Level III, CEN B6, and STANAG Compliance. The Field Shield family of products meets CIP-014 standards and IEEE/NEC grounding requirements. All ballistic testing is conducted in accordance with ARL test procedures and oversight. All ballistic testing is conducted in accordance with ARL test procedures and oversight

Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) simulation are powerful engineering tools used to analyze and optimize the performance of Field Shield products. FEA focuses on structural analysis, helping us understand how different components of our products will respond to various loads and stresses. By creating a virtual model of the product and applying mathematical equations, FEA enables us to predict deformations, stresses, and failure points, thus guiding the design process for durability and safety. CFD simulation, on the other hand, deals with fluid/aerodynamic flow and heat transfer within our products. It helps us assess thermal management, fluid dynamics, aerodynamics, and pressure distribution, ensuring efficient cooling and protection against overheating. During the testing phase, FEA and CFD simulations help us validate the design’s performance, making necessary adjustments before manufacturing to guarantee that Field Shield products meet the highest quality and performance standards.